Tel: 860-571-3602 | info@hartfordtechnologies.com

Quick disconnect & fast coupling is an essential part of the manufacturing process. Regardless of manufacturer, all quick connect/ disconnect couplings have two common parts: a plug & a socket.

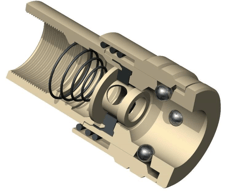

Quick disconnect fittings are used to provide fast and easy connection and disconnection of fluid or air lines. These fittings are also known as quick connects or quick release couplings. They are used to replace fitting connections that would require tools to assemble and disassemble. They are designed with a spring-loaded ball latching mechanism, which automatically locks the two halves of the fitting together when they are pushed together. To release the connection, the sleeve is pulled back and the balls are unloaded to release the connection. The quick disconnect advantage is that this can be done quickly and by hand.

Quick disconnect fittings are used to provide fast and easy connection and disconnection of fluid or air lines. These fittings are also known as quick connects or quick release couplings. They are used to replace fitting connections that would require tools to assemble and disassemble. They are designed with a spring-loaded ball latching mechanism, which automatically locks the two halves of the fitting together when they are pushed together. To release the connection, the sleeve is pulled back and the balls are unloaded to release the connection. The quick disconnect advantage is that this can be done quickly and by hand.

The precision of the ball is important in order to provide a uniform connection on all the balls in the head unit. Typically, the grade of balls used will be grade 100 or better. The material selection is important because depending on the fluid or air going through the connection the material will need to be compatible. Common materials are stainless steels and brass.

Hartford Technologies has supplied custom products to customers in a diverse range of industries since the 1930s. Bearings & rollers have changed over that time but some things have not: Hartford remains committed to responsible manufacturing even in times of uncertainty, as evidenced by our ISO 9001 and 14001 certifications and expert engineers. To learn more, we invite you to contact us today.