Tel: 860-571-3602 | info@hartfordtechnologies.com

Big changes are rolling in to the Hartford Technologies headquarters! Recently, we acquired a state of the art precision ball inspection machine, the Aviko G2. Unlike other machines, the quality control provided by the Aviko G2 is carried out simultaneously by three sensors: Electro-optical sensor (EOT), Eddy current sensor (ECT) and Vibration sensor (EVT). Combining multiple quality control and inspection checks results in a more precise ball with fewer surface and subsurface defects.

The first AVIKO ball scanner premiered in 1961. Since then, the AVIKO precision ball inspection machines have become best sellers worldwide. Today, the company has fully embraced the digital age as the newest AVIKO G2 machine has a faster microprocessor, an LCD screen, improved functions for ball inspection, and wifi capabilities.

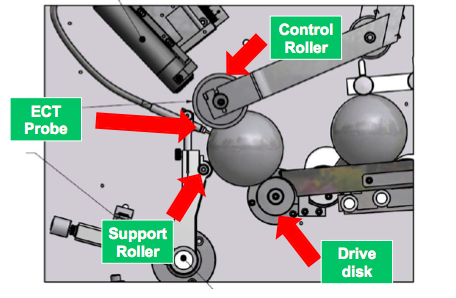

The Aviko G2 machine consists of two symmetrical mirrors with separately functioning sorters on the left and the right sides. The automatic sorting function can be undividually controlled and adjusted (one side can sort while the other one can be adjusted.)

Drive disk: This helps precisely drive and control speed of moving parts. Motcon technology ensures that the precision ball is transported efficiently through the machine. The driving disc revolution and speed of diameter sorter roller is easily adjustable.

Control roller: These rollers have the capability to check any diameter desired, without the need of changing them for each specific diameter.

Support roller: These rollers hold the precision balls in place during the inspection process.

As mentioned above, three sensors (EOT, ECT, and EVT) perform quality control.

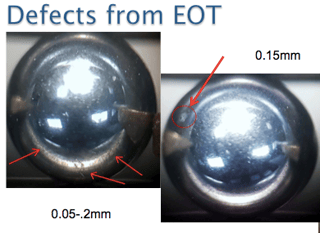

The New Electro Optional sensor (EOT), which is 100% digital in the AVIKO G2, detects defects in seven defectoscopic modes at once. This completely new defectoscopic method ensures higher signal of inspection due to increased sensitivity. Measured data can be adjusted directly on the 15" TFT touch screen monitor. The EOT can record 100,000 measurements per second!

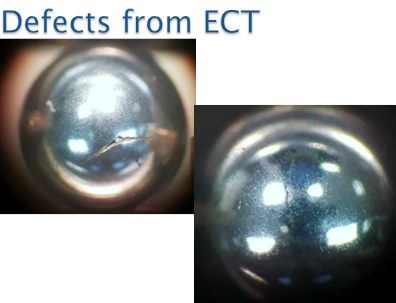

The Eddy Current sensor (ECT) Capabilities

The Eddy Current sensor (ECT) detects and evaluates cracks in the precision balls. With the AVIKO G2's ECT, frequency can be adjusted with reference to depth of penetration required to measure the cracks.

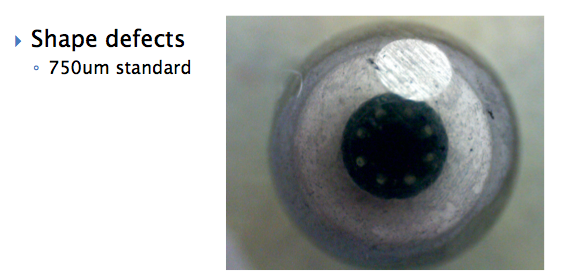

The Vibration Sensor (EVT) allows us to reject balls with large shape defects. Irregularly shaped balls disrupt smoothness of the ball rolling.

Once the balls have passed through EOT, ECT, and EVT sensors, the AVIKO sorts the balls into three different quality groups:

Balls categorized as good have passed each sensor's quality controls. If AVIKO deems a ball as "repairable", this means that the EOT sensor detected minor surface defects. Irrepairable balls have been rejected by ECT and/or EVT for major surface and subsurface defects.

At Hartford Technologies, we acquired the AVIKO G2 because we recognize the high expectations needed for quality precision ball bearings and are proud of our ability to rise up to meet them. If you would like to learn more about our exceptional variety of precision balls for your industry, we invite you to contact us today.