The Project

The Project

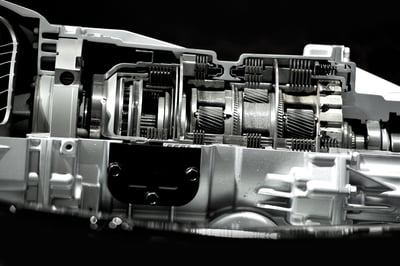

A major automotive customer asked Hartford to quote a bearing race for a vehicle powertrain application.

What Hartford Provided

The previous supplier had produced this part using an expensive forging process. The OEM wanted a lower cost alternative that still met a very demanding part strength requirement.

What we did

Hartford Technologies engineered a lower total cost solution by developing a process that used tubing as the raw material. High throughput machining and grinding operations efficiently produced the part. We worked with an advanced heat treating supplier to customize an austempering process that met the customer’s demanding part strength metrics.

This heat treating process resulted in a part with exceptional toughness, an impressive contrast with the hard but brittle parts that can result from conventional heat treating. Advanced quality tools such as statistical process control ensure that a high Cpk is maintained.