Tel: 860-571-3602 | info@hartfordtechnologies.com

The principles of lean manufacturing have revolutionized the automotive industry, allowing them to cut costs and improve their efficiency. At Hartford Technologies, all of the automotive components that we manufacture are perfect for being integrated with lean manufacturing principles. If you would like to make the most of lean manufacturing in your business, consider implementing the following tools.

Kaizen

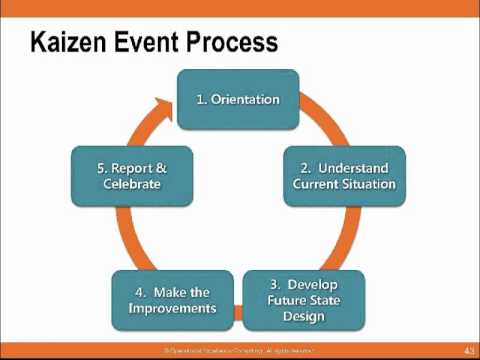

In Japanese, Kaizen means "continual improvement". This lean manufacturing tool dictates that processes be continually improved in order to eliminate waste and boost efficiency. In the automotive industry, Kaizen is often implemented in order to address problems and provide solutions in the assembly line process.

Learn More About Kaizen

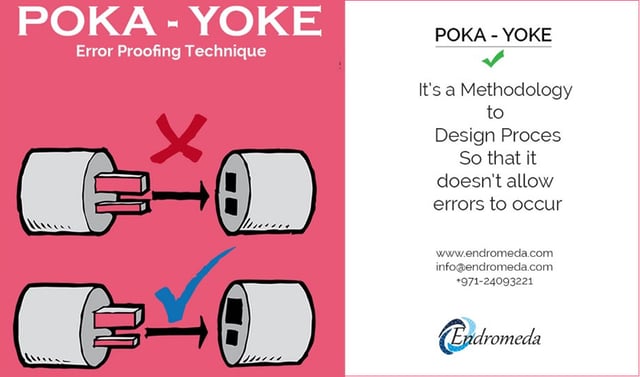

The goal of Poka-Yoke is to prevent mistakes from becoming defects, which is a crucial aspect of efficient, quality manufacturing. In the automotive industry, one example of Poka-Yoke being implemented is a conveyor belt that will reject a part if it is underweight and therefore prevent a mistake from becoming a defect that makes it through the assembly line.

Learn More About Poka-Yoke

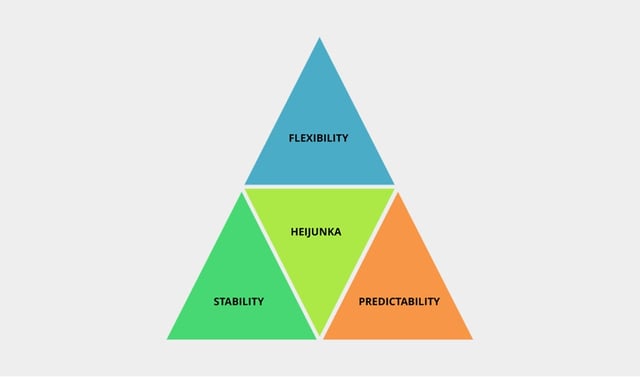

The Japanese word for "leveling" Heijunka is used to level out the production process to reduce batching and ensure that a consistent number of components are produced each day. This enables companies in the automotive industry to optimize their manufacturing process for a specific number of items manufactured rather than having that number vary on a day-to-do basis.

Learn More About Jeijunka

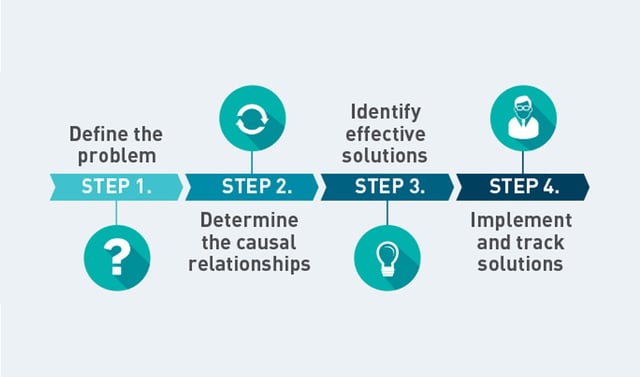

A3 Problem Solving is a method of problem solving used to find flaws, explore solutions, and implement those solutions in order to achieve a desired goal. A3 Problem Solving was first implemented by Toyota and offers a lot of value to companies in the automotive industry.

Learn More About A3 Problem Solving

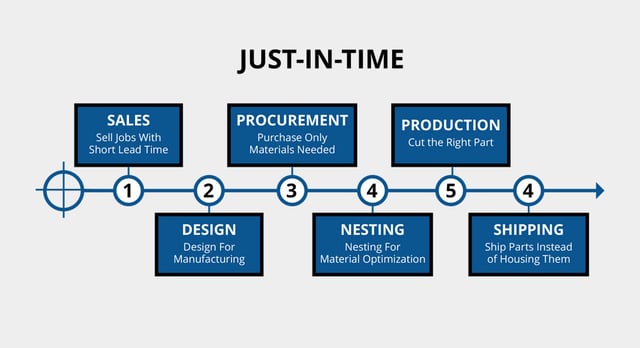

Just in Time manufacturing dictates that products be produced when the customer wants them in the amount the customer needs. This process enables companies to reduce their inventory and eliminate waste by ensuring their products are sold as soon as they roll off the assembly line.

Learn More About Just in Time

The 7 Wastes lean manufacturing tool is implemented by Toyota and is perfect for companies in the automotive industry. This tool helps companies analyze the seven areas where waste commonly occurs and provides steps for them to eliminate that waste.

Lean More About 7 Wastes

RCA dictates that it's much better to get to the root cause of the problem rather than treating its obvious symptoms. In automotive manufacturing, which can be quite complex, it can often be difficult to find the root cause of a problem. By using the RCA tool, companies can make spotting and fixing the root cause of problems much easier.

Learn More About Root Cause Analysis

Six Big Losses highlights the six most common causes of inefficiencies in production and provides companies with the steps they need to use in order to address these causes.

Learn More About Six Big Losses

Like RCA, the 5 Whys tool is designed to help companies find the root cause of a problem rather than treating its symptoms. In the automotive industry, companies can use the 5 Whys tool in order to ask the questions that need to be asked about their manufacturing process and find the correct answer to those questions.

Learn More About 5 Whys